Mining Methods at Nacozari, Sonora, Mexico (1912)

6 de diciembre de 2023

By D. C. Livingston

The Pilares de Nacozari mine is located in Sonora, 75 miles south of Douglas, Arizona. The town of Douglas is on the international boundary and is the place at which the ores from the Bisbee mines are smelted. The Moctezuma Copper Co. owns the mines at Nacozari, and the copper concentrates shipped to the Copper Queen smelter, at Douglas, make a good smelting mixture with the Bisbee ores. The Moctezuma Copper Co. and the Copper Queen smelter at Douglas, as well as the railroad from Douglas to Nacozari, are owned by the Phelps, Dodge & Co.

The ore deposit occurs in the form of a large ellipse with a major axis of approximately 2,000 ft. and a minor axis of about 600 ft., the major axis bearing about 9° W. of N. The whole of this ellipse is more or less mineralized; the surface being principally an iron gossan with some occasional copper stains. Below the oxidized zone, which is not more than 50 ft. deep, the minerals are pyrite and chalcopyrite, with occasional seams of chalcocite, the latter being rare. There appears to be no well-marked zone of secondary enrichment, the oxidized gossan over the greater part of the deposit changing suddenly to what is apparently the original unaltered ore. The copper values are concentrated around the perimeter of the ellipse, and it is principally around this perimeter that the mining is done. The ore mined averages a little more than 3 percent, of copper, with a small amount of silver, less than an ounce per ton. Some ore of considerably higher grade than this has been shipped, however, but the above average is of the mill-run. The ore is wider near the two ends of the ellipse than along the sides and is mined in some cases to a width exceeding 200 ft.

The country rock for the first vertical 500 ft. is a volcanic acid breccia, probably rhyolitic; below this point, it is more a basic breccia, probably andesitic. The contact is plainly marked on the surface by bluffs in one place, but it is almost impossible to trace it underground on account of the similar appearance of the two rocks when freshly broken. The change in formation has no apparent effect on the ore; if anything, it is somewhat richer but more bunchy in the lower formation, but work enough to verify this statement has not yet been done. The contact between the mineralized rock of the ellipse and the unmineralized country rock is plainly marked by a more or less definite wall, the rock on both sides of this wall, however, being the same. The ore is extracted from this wall towards the center of the ellipse until it becomes too low-grade to mine, although the whole of the interior of the ellipse would run almost 1 percent of copper.

This property presents a very interesting study of the origin of ore deposits and was being examined and mapped last summer for the Moctezuma Copper Co. by J. M. Boutwell, formerly of the U.S. Geological Survey. There is a similar deposit at Mount Morgan, Australia, which also is in the form of an ellipse, though less than half the size of the one at Nacozari. I believe it is worked chiefly for the gold-values, and the whole of the ellipse is more or less workable. At the Braden copper mine in Chile, there is an ore body of this same shape, but there the ore occurs along a contact of a volcanic neck which is intrusive in an older rock and different, while at Nacozari the country rock and the interior of the ellipse are apparently the same.

The mine is opened by two 3-compartment shafts, situated one at each end of the ellipse, and an adit tunnel about a mile long which taps the deposit at a point about 600 ft. below the collar of the shafts. This adit is large enough to allow narrow-gauge, 25-ton railroad cars to load from the mine chutes, and it is chiefly due to this cheap handling of the ore that the enterprise has become so commercially successful. The railroad runs to the top of the bins above the concentrator, which is situated on the Nacozari railroad at the town of Nacozari, about 5 miles from the mine. From here the concentrates are shipped to the smelter at Douglas, Arizona The daily output of ore is between 1,500 and 2,000 tons.

The levels in the mine are 100 ft. apart, and the general plan is to use every alternate level as a stoping base, the intermediate levels being used for development, ventilation, and the distribution of waste to the stopes that are being filled. At the present time, practically all the ore is being mined above the adit-level, which is known as the “700,” and at the present rate of output, there should be, above this level, on a rough estimation, an ore supply for at least 10 or 12 years. The shaft at the north end has been sunk to the 1,000-ft. level and some work has been done on this level, as well as on the 800- and 900-ft. levels.

Owing to the scarcity of timber in the neighborhood, and to the high price of imported timber, it has been necessary to adopt mining methods which would eliminate the use of timber as much as possible. The nature of the rock is such that while it is not hard to drill or blast, it stands without timber in a most remarkable manner in most parts of the mine. This characteristic of the rock has also prevented the use of the caving and top-slicing methods, which are being used so successfully at Cananea in some of the mines. Accordingly, some system of underhand stoping had to be devised, and the following two methods are used:

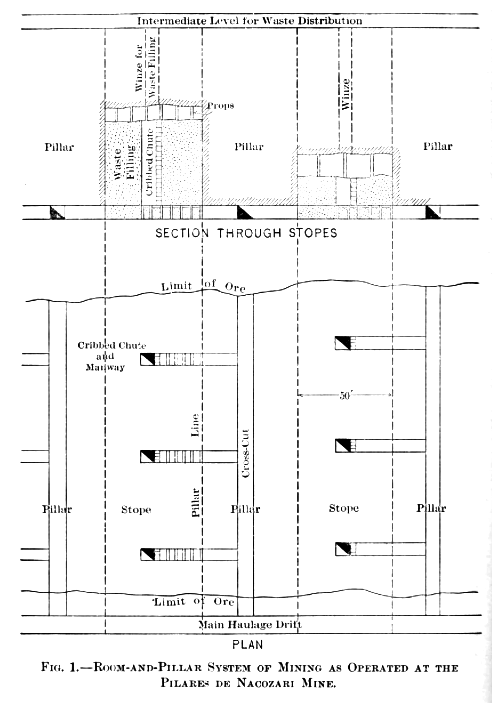

1) The old method. Fig. 1, which is room-and-pillar with waste-filling as the work progresses.

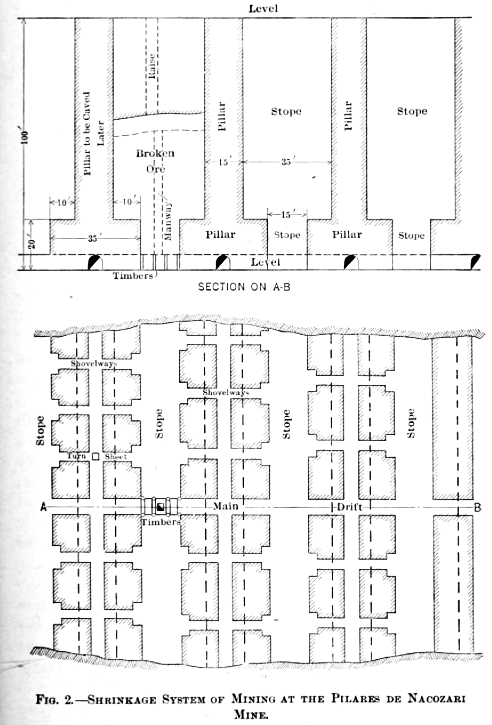

2) The new method. Fig. 2, which is shrinkage with waste filling after all of the ore has been extracted.

1) With the room-and-pillar method the mine plan is laid off into pillar lines at right angles to the strike of the ore and placed 50 ft. apart, dividing it into alternate stopes and pillars.

A main working drift is run approximately parallel to the strike, and cross-cuts are turned off every 100 ft. in the pillars. From these cross-cuts, right-angle headings are turned off, and every 50 ft. run to the center of the stope, and from these the sillfloor is cut out to the limits of the ore and to the pillar-lines, making the stope 50 ft. wide. The roof, where necessary, is supported by props or cribs, and a 6-ft. cut is then taken upward with stopping drills, the blasted ore being drawn off immediately, and filling run in from the level above through winzes to within 4 or 5 ft. of the roof. The short drifts from the crosscuts are timbered through the filling, and cribbed chutes and man-ways are carried up from the ends of these. In a stope 150 ft. long, there would be three of these chutes and man-ways.

There were no pillars being extracted when I was there, and it was probably the apparent difficulties of removing these pillars without losing a large amount of ore by mixing with waste, which led to the adoption of the new method.

2) With the shrinkage method, designed by C. A. Smith, the use of timber is almost entirely eliminated, as not even timbered chutes are used.

Cross-cuts are turned off from the main haulage drift every 50 ft. parallel to the pillar lines, and extending to the limits of the ore.

The next step is driving what are called the “stopes,” which are breasts 15 ft. wide and the height of an ordinary drift. These are driven parallel to the cross-cuts, and midway between them, and are carried to the limit of the ore. From the cross-cuts “shovel-ways” are turned off at right angles at intervals of from 20 to 25 ft., and are driven to connect with the stopes. Turn sheets are placed at the mouths of the shovelways. The ground is now ready to commence underhand stoping. The stopes are carried up the same width (15 ft.) with stoping drills to a height of 20 ft. above the floor and are then widened 10 ft. on each side, making them 35 ft. in width, with 15 ft. pillars in between.

The machines are set up on the broken ore, enough being drawn out through the shovelways to keep a working clearance. The stope is continued up in this manner to the next stoping-level. This work was started last summer, but it is evident that the main drifts will have to be timbered where the stopes cross them, in order to keep the broken ore off of the track, and cribbed man-ways built up through the broken ore at these points, but aside from this, with the exception of an occasional prop, no timber at all is used. There would be no absolute necessity for man-ways through the broken ore, as the stope can be entered by means of the winze from the level above.

The shovel-ways, which are merely rock chutes, have been used in the mine for a number of years in the narrower portions of the vein instead of timber chutes. The reasons for their adoption are:

1) No timber required.

2) Ease and safety in blasting large boulders, which can be more safely and easily blasted in the shovel-ways than in the stopes, and without interfering with the work.

3) All work, except timbering, is done by contract with the natives, and it was found that unless all the rock was broken in the stopes sufficiently small to pass a chute readily (a difficult and expensive item in ground that breaks big where shrinkage is employed), it was just as cheap to have it shoveled into the car as to draw off from a chute that was continually hanging-up, and the expense of placing the timber was also eliminated.

In mining the pillars in the shrinkage system, I believe the plan is to put up raises in the pillars and from the raises to shatter the pillars with heavy shots so that the pillars will cave when the ore is drawn out of the stope. If this method works out as expected at least 95 percent, of the ore should be recovered.

As regards the comparative costs of the two systems: stoping in the wide stopes by the shrinkage system had not progressed sufficiently in the summer of 1911 to give a complete comparison, but what figures were available pointed to a considerable saving in the shrinkage over the room-and-pillar system. This should be the case after the sill floor has been opened up, because, in the shrinkage system, there is no rock handled in the stopes until the ore is drawn out, whereas, in the room-and-pillar system both the ore and waste filling have to be handled in the stopes in wheelbarrows.

Presented by invitation at a meeting of the Spokane Local Section of the

American Institute of Mining Engineers

February, 1912

Cover Photo: Nacozari de García, Sonora (unknown date). Arizona Historical Society

© All Rights Reserved