History of the Moctezuma Copper Company

22 de febrero de 2022

By John S. Williams, Jr.

(1922) – The Nacozari Mining District is one of the oldest in Northern Sonora. The silver mines at Churunibabi, situated four miles north of the present town of Nacozari, have been worked more or less continuously for some 300 years. Tailing deposits from this old mine have been discovered underneath several feet of soil. In Baron Von Humboldt’s Political Essay of New Spain, published in Paris in 1808, he mentions Nacozari as being one of the pueblos in Sonora, which were mining centers, but did not give the names of any of the producing mines.

The famous lost Huacal mine was in this district, to which legends attribute a marvelous production. Is more than likely that the present San Pedro mine of The Moctezuma Copper Company is the lost Huacal, as the surface workings of the property are quite ancient, and the legends say that a light on the dumps of the Huacal could be seen from the church door in Nacozari, and it is a fact that a light on certain parts of the San Pedro can be seen at Nacozari Viejo.

The oldest copper mine in the district is La Fortuna, formerly called La Cobriza. At one time, this mine was owned by a firm of merchants in Guaymas, who smelted the ores at a place now called Granaditas, and packed the resulting matte on mule back to Guaymas, from which place it was shipped by sailing vessel to Swansea, Wales.

In the early eighties, W. Farish and Meyer Zulick were operating a small adobe smelter at a point about one mile south of Granaditas, treating ores from La Fortuna, and there were several other Americans in the district working the San Pedro, San Pablo, Bella Unión and Gran República mines.

The Moctezuma Concentrating Company, with headquarters in Jersey City, came into the district about this time and acquired La Fortuna, Bella Unión, and San Pedro mines, erecting a small mill and blast furnace at Nacozari Viejo, which they operated for a number of years with varying success. During this time, the company acquired some claims at Los Pilares, which was beginning to attract some attention on account of the heavy iron and copper stained pillars which gave the camp its name. In the latter eighties, Gains Paddock of St. Louis bought the San Pablo mine and erected a mill on it, but the enterprise proved unprofitable.

In the early nineties, the Moctezuma Concentrating Company gave an option on its properties to Col. John Weir, who succeeded in interesting the Guggenheims, who, at that time, were just getting into the copper business, and this firm, in 1895, organized the Moctezuma Copper Company to take over all the holdings of The Moctezuma Concentrating Company.

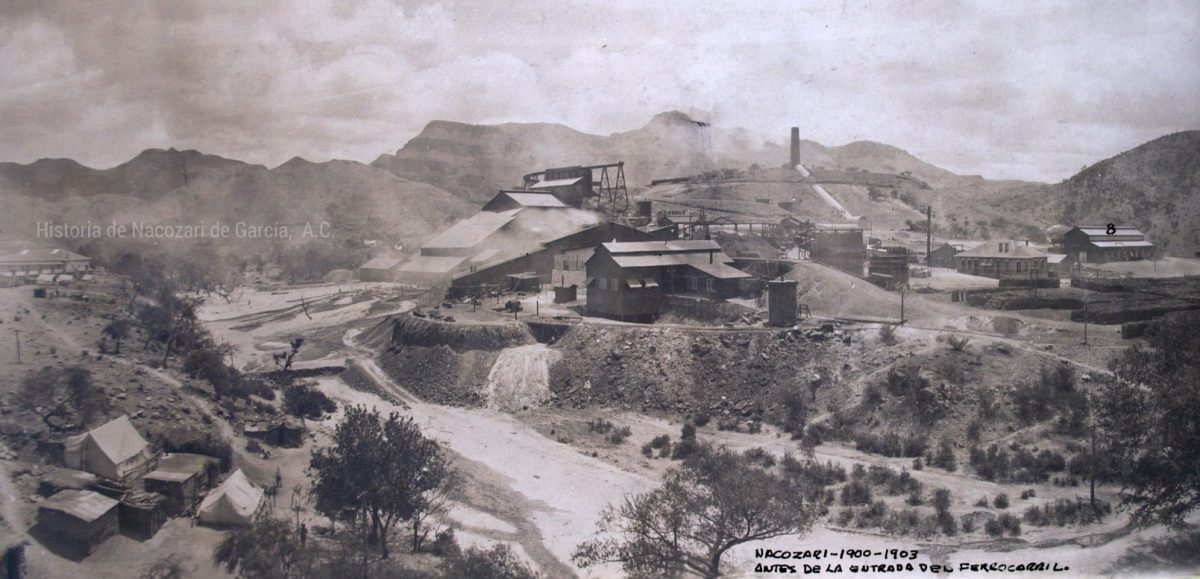

The new company commenced development at Los Pilares and opened up a very attractive orebody, second and third levels, at the same time continuing the operation of the small mill and smelter at Nacozari Viejo, the only place in the district where water in sufficient quality for a mill and smelter could be obtained, and as the company realized that a large investment would be required to fully develop the mines, developed a new smelter and mill; constructed a railroad from the United States as well as a railroad from the mine to the mill, the Guggenheims decided to sell the property and offered the same to Phelps Dodge & Co.

After an examination of the property by Dr. James Douglas, assisted by Dr. L. D. Ricketts, Mr. Ben Williams, Mr. Walter Douglas, and Mr. J. S. Douglas, the entire holdings of The Moctezuma Copper Company were purchased in 1897.

The company now commenced an active campaign of mine development and made tests in the small mill and smelter at Nacozari Viejo to determine the best method of treatment of the ores. It was early recognized that the site at Nacozari Viejo did not give enough room for a plant of the size that would be required to ensure the financial success of the enterprise, and a new site was selected at a point on the river six miles north of the old plant, which gave sufficient room for the new plant and town and at the same time was conveniently located as a terminal for the railroad from the mine; also reducing the length of the proposed railroad from the border and reducing the cost of the same by saving of six miles of very heavy grading. The name of this place was changed from Placeritos to Nacozari.

Work was soon commenced on the new town in order to house the workmen who would be required for the construction of the plant, and surveys were made to determine the best route for a railroad from the Arizona border, the Nacozari Railroad Company being organized to build the road. The starting point for several surveys was Naco, Arizona. This place came into existence because it was supposed, for some time, that a railroad to Nacozari could have to start from that point (Naco is an abbreviation of Nacozari), but no reasonable gradients could be found over “Snake Ridge” so that it was finally decided to make a survey from the lower Sulphur Springs Valley at a point were Douglas no stands. This route proved practicable and grading started in 1900. The road reached Cos, 89 kilometers south, early in 1901. Cos remained the southern terminal of the road for three years, awaiting results of mine development on the levels below the third, but by 1903, the development on the lower levels was soon encouraging that the railroad was completed into Nacozari early in 1904. During this time, the first railroad surveys were being made. Plans had been prepared for the new mill, smelter, converting plant, and powerhouse, which necessary shops and the mine put into shape for production. All of this construction, as well as the mine railroad, was finished and the plant was put into operation several months before the railroad from Douglas could be utilized. Consequently, all rails and locomotives for the mine railroad, all machinery for mill and smelter, gas producers, and engines for the powerplant were hauled by teams from Naco, at a distance of 90 miles.

The first plant consisted of a concentrating mill with a capacity of 500 tons per day, two 42″ x 120″ blast furnaces with two stands for barrel-type converters; all machinery being electrically driven. The power plant consisted of eight 80 hp Crossley gas engines belted to D.C. generators, to which were added later two 200 hp engines for the same make; the gas for the same being generated in Loomis-Pettione producers. Later, in order to ensure steady power for the smelter, an auxiliary steam plant was added. At first, anthracite coal was used for gas making, but this was very expensive and entailed a great loss of time and expense in the barring out of cylinders from the producers so that experiments were made in the use of wood, which proved so successful that only wood was used up to the time that the available supply became exhausted.

With the completion of the railroad into Nacozari in 1904, it was decided to ship all concentrates to the Douglas smelter, as on account of the furnace burden consisting almost entirely of fine material, the flue dust losses at Nacozari were heavy; consequently, all smelting operations were stopped in that year. By the year 1907, mine developments had reached a point, which justified a larger mill, and one of 1,500 tons daily capacity was planned, which went into operation in the fall of 1908. By this time, the available supply of wood was also about exhausted, so it was necessary to abandon the use of the gas engines. While the new mill was under construction, a new power plant was installed, which consisted of three 1,000 K.W. Curtis Vertical Turbines and four 435 hp Stirling boilers, and a new electrical transmission line to the mile was built. In the new mill, the old flow sheet was retained, but improved machinery with better arrangements made a better extraction with a considerable decrease in costs. By the installation of additional equipment from time to time, this mill was finally brought up to where it could treat about 2,500 tons per day, but as the ores at dept were becoming of a more disseminated type, it was realized by 1916 that the flowsheet was becoming unsuited to the ores then being mine, and would be entirely unsuited within a very few years and for rather a long period of time. Tests on all flotation treatment and combined gravity and flotation treatment were made, all results being in favor of the latter.

As it was considered advantageous to use the old mill building, the plan was to change one section at a time, while continuing operating the remaining sections of the old mill and the remodeling was commenced in January 1920.

The depression in the copper industry in 1912, however, caused The Moctezuma Copper Company to suspend operations in common with nearly all copper producers. This allowed the removal of all the old equipment and more rapid reconstruction so that the first unit of 1,000-ton capacity was put into operation in June 1922. The mill now consists of three 1,000-ton units with space for another unit of the same capacity whenever it is considered desirable to install it.

The wrecking of one of the Curtis turbines in November 1918, made it necessary to consider additional power, and as the company was able to make it a favorable contract for Mexican oil, it was decided to install diesel engines. The new power plant was installed, and now consists of–

4 – 1,250 hp Nordberg-Carels Diesel Engines

2 – 2,000 hp Nordberg-Carels Diesel Engines

The Moctezuma Copper Company has always shown a keen interest in the welfare of its workmen, and in addition to furnishing them sanitary living quarters at a nominal rent with free water and electric lights, hospitals, safety first instruction, etc., has furnished free libraries, clubhouses, where natives and foreigners, heads of departments and laborers all meet on an equal footing, and it has always made it a point to promote natives to positions of responsibility where they have proven their ability. This policy has brought good results, and in its 25 years of operations, the company has never had any serious misunderstandings with its workmen.

February 1, 1922

About the author:

John S. Williams, Jr. was son of a former Bisbee mayor. He came from a family deeply rooted in mining and rose to become one of the pioneer mining men of the Southwest. Building on his family’s legacy, he played a central role in the development of northern Mexico’s mining industry, serving as the active general manager of the Moctezuma Copper Company and the Nacozari Railroad.

© All Rights Reserved